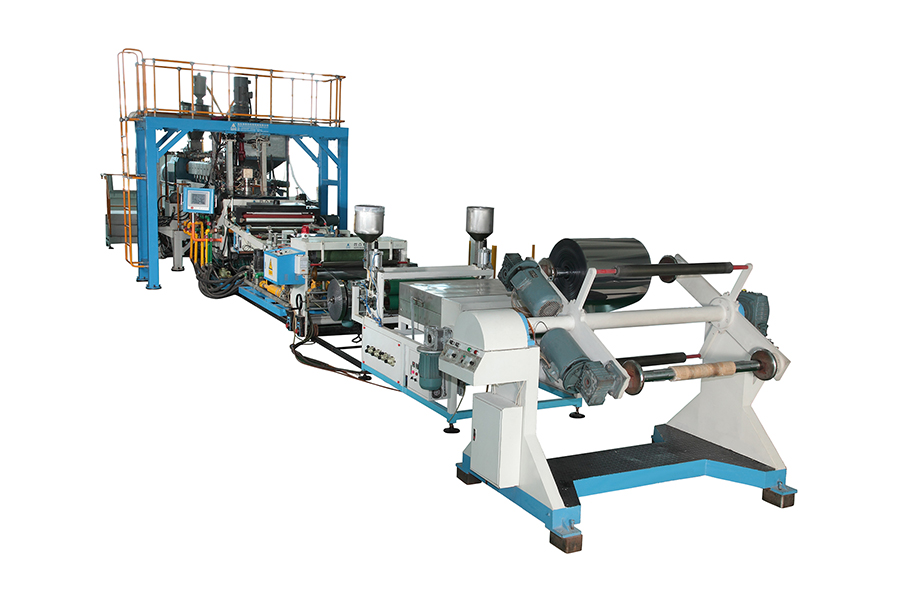

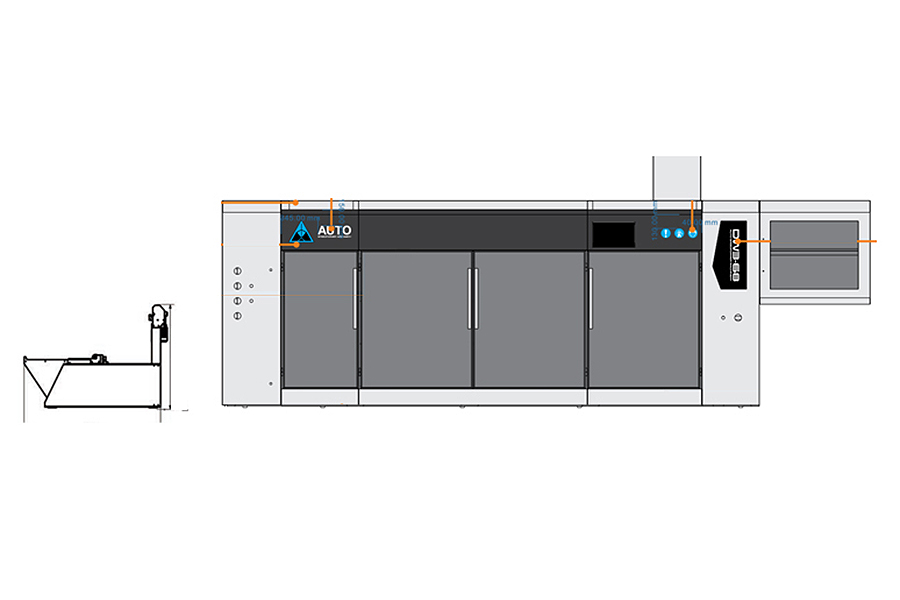

Twin Screw Plastic Extruder (PET Sheet Extrusion)

Tekheniki Parameter

WJP(PET)75B-1000 Twin Screw Plastic Extruder (PET Sheet Extrusion)

| Lisebelisoa tse sebetsang | Tlhaloso ea Screw | Botenya ba maqephe | Bophara ba leqephe | Bokhoni ba ho ntša | Matla a kentsoeng |

| mm | mm | mm | kg/h | kW | |

| APET, PLA | Φ75 | 0.18-1.5 | ≤850 | 300-400 | 280 |

Likaroloana

1.The screw element e sebelisa conjugate type double thread screw e nang le moralo oa ntlafatso ea komporo le machining a nepahetseng. Ntle le moo, screw e entsoe ka motsoako oa multivariate modular kaho, e nang le ho itlhoekisa le ho feto-fetoha ha maemo.

2. E ipapisitse le boiphihlelo ba lilemo tsa boqapi ba sekoaelo sa screw, AUTO e ka etsa tlhophiso e nepahetseng ea motsoako oa li-screw elements ka thuso ea thekenoloji ea software. Ka hona, e ka hlokomela phetiso ea lisebelisoa tsa polasetiki, ho hloekisoa ho tsoakiloeng, ho kuta le ho qhalakanngoa, homogenization, volatilization le devolatilization, boloka khatello le extrusion le mesebetsi e meng ho latela lisebelisoa tsa bareki le theknoloji ea ho sebetsa.

3. Moqomo oa mochini o entsoe ka likhokahano tse peli tsa vacuum e qetang ho netefatsa ho ntša mouoane oa metsi ka botlalo le likhase tse ling tse sa tsitsang.

4. The twin screw plastic extruder e entsoe ka melt dosing pump ho netefatsa tlhahiso ea bongata ka khatello e tsitsitseng, e ka boela ea thusa ho hlokomela taolo e koetsoeng ea khatello le lebelo.

5. Kakaretso ea mochine o amohela tsamaiso ea PLC ea ho laola, e ka khonang ho lemoha ho laola ka mokhoa o itekanetseng bakeng sa ho beha parameter, ts'ebetso ea letsatsi, maikutlo, ts'oaetso le mesebetsi e meng.

Molemo

E 'ngoe ea lintlha tse ka sehloohong tsa li-fin screw plastic extruder ke likarolo tsa tsona tsa screw. Ho 'nile ha nkoa tlhokomelo e kholo ho netefatsa katleho e kholo le nako e telele ka ho sebelisa sekoti sa conjugated twin-flight. Moqapi ona o ikhethang o kopantsoe le theknoloji ea ho ntlafatsa k'homphieutha le ho sebetsa ka mokhoa o nepahetseng, ho fella ka ts'ebetso e phahameng. Li-screw elements li boetse li na le moaho oa modular bakeng sa ho itlhoekisa le ho feto-fetoha ha maemo. Sena se netefatsa ts'ebetso ea tlhahiso e boreleli le e sa sitisoeng, ho fokotsa nako ea ho theoha le ho eketsa tlhahiso.

Lilemo tsa boiphihlelo ba moralo oa meralo ea screw li re lumella ho ntlafatsa ts'ebetso ea extruder. Ka thuso ea theknoloji ea morao-rao ea software, re ka khona ho hlophisa metsoako ea li-screw element. Sena se bolela hore li-extruder tsa rona li khona ho fetisa le ho etsa polasetiki hantle, ho netefatsa tlhahiso e tsitsitseng ea boleng bo holimo. Theknoloji ea rona ea software e phetha karolo ea bohlokoa ho finyella maemo a nepahetseng a ts'ebetso, ho netefatsa hore bareki ba rona ba khona ho hlahisa litekanyetso tse phahameng ka ho fetisisa tsa PET sheet.

Monyetla o mong oa bohlokoa oa li-extruder tsa rona tsa polasetiki tse mafahla ke ho feto-fetoha ha tsona. Hore na o ntse o hlahisa PET sheet bakeng sa ho paka, thermoforming kapa ts'ebeliso efe kapa efe, li-extruder tsa rona li ka fihlela litlhoko tsa hau tse ikhethang. E khona ho sebetsana le mefuta e mengata ea lisebelisoa, e fana ka phetoho e kholoanyane mosebetsing oa hau oa tlhahiso. Ho feta moo, li-extruders tsa rona li etselitsoe liphetoho tse bonolo le tse potlakileng, tse u lumellang hore u fetole habonolo lipakeng tsa lifomate tse fapaneng tsa sehlahisoa. Ts'ebetso ena e fapaneng e u bolokela nako le chelete, e etsa hore li-extruder tsa rona e be tharollo e theko e tlaase bakeng sa litlhoko tsa hau tsa PET sheet extrusion.