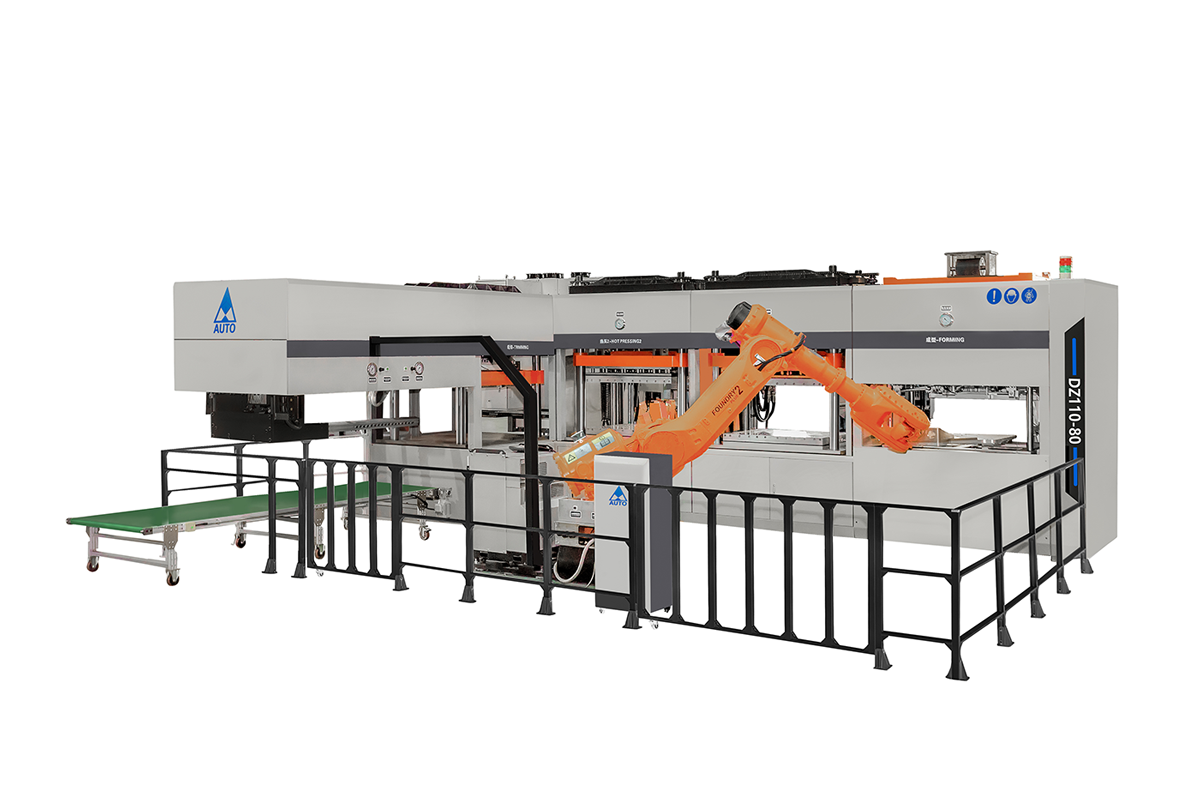

DZ130-110 mochini o etsang thermoforming oa servo o felletseng oa taolo ea fiber pulp

Mochini oa mold oa Bagasse pulp, mochini o etsang li-tableware o bonolo oa eco, mochini oa tlhahiso ea pampiri ea lijo tsa mots'eare.

| Mohlala | 3-axis gantry manipulator |

| Mofuta oa ho etsa | Ho bopeha ka ho kgutlisana |

| Boholo ba sebopeho | 1300mm x 1100mm |

| Max. Botebo ba ho theha | 120 limilimithara |

| Mofuta oa ho futhumatsa | Motlakase(208kw) |

| Max. Tobetsa khatello | 80 ton |

| Max. khatello ea ho fokotsa | 80 ton |

| Tšebeliso ea matla | 90-130kwh Itšetlehile ka sebopeho sa sehlahisoa |

| Tšebeliso ea moea | 0.5m³/mots |

| Tšebeliso ea vacuum | 8-12m³/min |

| Bokhoni | 1200-2400kg / letsatsi E ipapisitse le moralo oa sehlahisoa |

| Boima ba 'mele | ≈39ton |

| Boemo ba mochini | 9.3m X 6.2m X 4.6m |

| Matla a lekantsoeng | 274kw |

| Lebelo la tlhahiso | 2.5 - 2.8 potoloho / min |

Lisebelisoa tse ngata ka har'a Packaging ea Fiber e Eco-Friendly Molded

♦ Tableware e lahloang

♦ Lebokose le Sekoahelo sa Lijo tse Potlakileng

♦ Litholoana tsa litholoana

♦ Sephutheloana sa indasteri

♦ Packaging ea boemo bo phahameng

♦ Likopi, Li-Lids, Mohope oa Mohope le Bajari

1) Sistimi e bohlale ea taolo ea HMI, ts'ebetso e felletseng ea ts'ireletso ea liphoso, le ts'ebetso ea senotlolo se le seng sa ts'ebetso e felletseng ea tlhahiso ea mochini.

2) Bokhoni bo phahameng ba tlhahiso, tšebeliso e tlase ea matla, Ho boloka matla ho feta 50% le keketseho ea matla e fetang 50%.

3) Taolo e bohlale ea mocheso: taolo ea libaka, ho boloka matla, ho futhumatsa libaka libakeng tse 16 ho ea holimo le tlase, beha mocheso o fapaneng ho latela botebo ba lihlahisoa.

4)Sistimi ea ho lubrication e iketsang

5) Fuselage ea tšepe e entsoeng ka matla a phahameng, e sa keneleng metsi le e khahlanong le kutu

6) Ts'ebetso e ikhethang le e ncha ea ho hatella ho chesang, sistimi e kholo ea ho ntša mouoane oa mouoane, taolo ea mocheso ea libaka ho netefatsa ho futhumala ho tšoanang ha karolo e 'ngoe le e' ngoe ka mekoting.

7) Ts'ebetso e bonolo ea ho kenya hlobo le ho laolla, ho ntlafatsa haholo ts'ebetso ea ho kenya le ho theola hlobo.

8) Seteishene sa ho kuta se na le sejana sa moea se akaretsang le silinda e akaretsang ea ho hlobolisa, e fokotsang haholo litšenyehelo tsa tlhahiso ea hlobo ea ho itšeha.

9) The manipulator e ncha ea ho fanyeha e phethela ts'ebetso ea othomathike ea lisebelisoa tse ka morao le ho bala ho bokella lihlahisoa.

E 'ngoe ea likarolo tsa bohlokoa tsa DZ130-110 ke taolo e nepahetseng ea mocheso, e lumellang ho bopeha ka mokhoa o tsitsitseng le oa boleng bo phahameng ba lihlahisoa tsa fiber pulp. Boemo bona ba ho nepahala bo netefatsa hore sehlahisoa se seng le se seng se finyella litekanyetso tse phahameng ka ho fetisisa tsa boleng le ho tšoarella.

Ho phaella moo, DZ130-110 e fana ka lebelo le tsotehang la tlhahiso le lebelo la potoloho ea lipotoloho tse 2.5 ka motsotso. Ts'ebetso ena e phahameng e eketsa tlhahiso le tlhahiso, e etsa hore e be se loketseng bakeng sa likhoebo tse batlang ho tsamaisa mekhoa ea tsona ea tlhahiso.

Ho feta moo, DZ130-110 e etselitsoe ho sebelisa lisebelisoa hantle. Moea o sebelisoang ke mochine ke 0.5 cubic metres feela ka motsotso, ho fokotsa litšila le ho fokotsa litšenyehelo tsa matla. Ho feta moo, matla a eona a sebelisoang ke 90-130kw·h, e leng se etsang hore e be khetho e ntle ea tikoloho le e theko e tlaase bakeng sa likhoebo.

Ka kakaretso, mochini oa thermoforming oa DZ130-110 o laoloang ka botlalo oa servo-control pulp molding ke tharollo ea maemo a holimo bakeng sa lik'hamphani tse hlokang lisebelisoa tse tšepahalang, tse sebetsang hantle haholo. Sistimi ea eona ea taolo ea servo, taolo e nepahetseng ea mocheso, lebelo la tlhahiso e potlakileng le tšebeliso e nepahetseng ea lisebelisoa e etsa hore e be letlotlo la bohlokoa bakeng sa likhoebo tse batlang ho ntlafatsa tlhahiso le litekanyetso tsa boleng.

Ebang u ka har'a liphutheloana, tšebeletso ea lijo kapa indasteri ea lihlahisoa tsa indasteri, DZ130-110 ke khetho e phethahetseng bakeng sa ho hlahisa mefuta e fapaneng ea lihlahisoa tsa fiber pulp. Ho feto-fetoha ha eona, ho sebetsa hantle le ho ts'epahala ho netefatsa hore o khona ho fihlela litlhoko tsa bareki ba hau ha o ntse o tsepamisitse maikutlo holim'a botsitso le ho baballa litšenyehelo.